When it comes to the food processing and packaging industry, cleanliness is of the absolute utmost importance. On average, a food recall costs large producers $10 million in direct costs alone. This is not even taking into account the indirect costs and losses suffered by a company after contamination and recall have taken place.

Automating your packaging line is a great way to reduce the risk of contamination and subsequent recall in your food processing and packaging business.

Clean and Cleanable

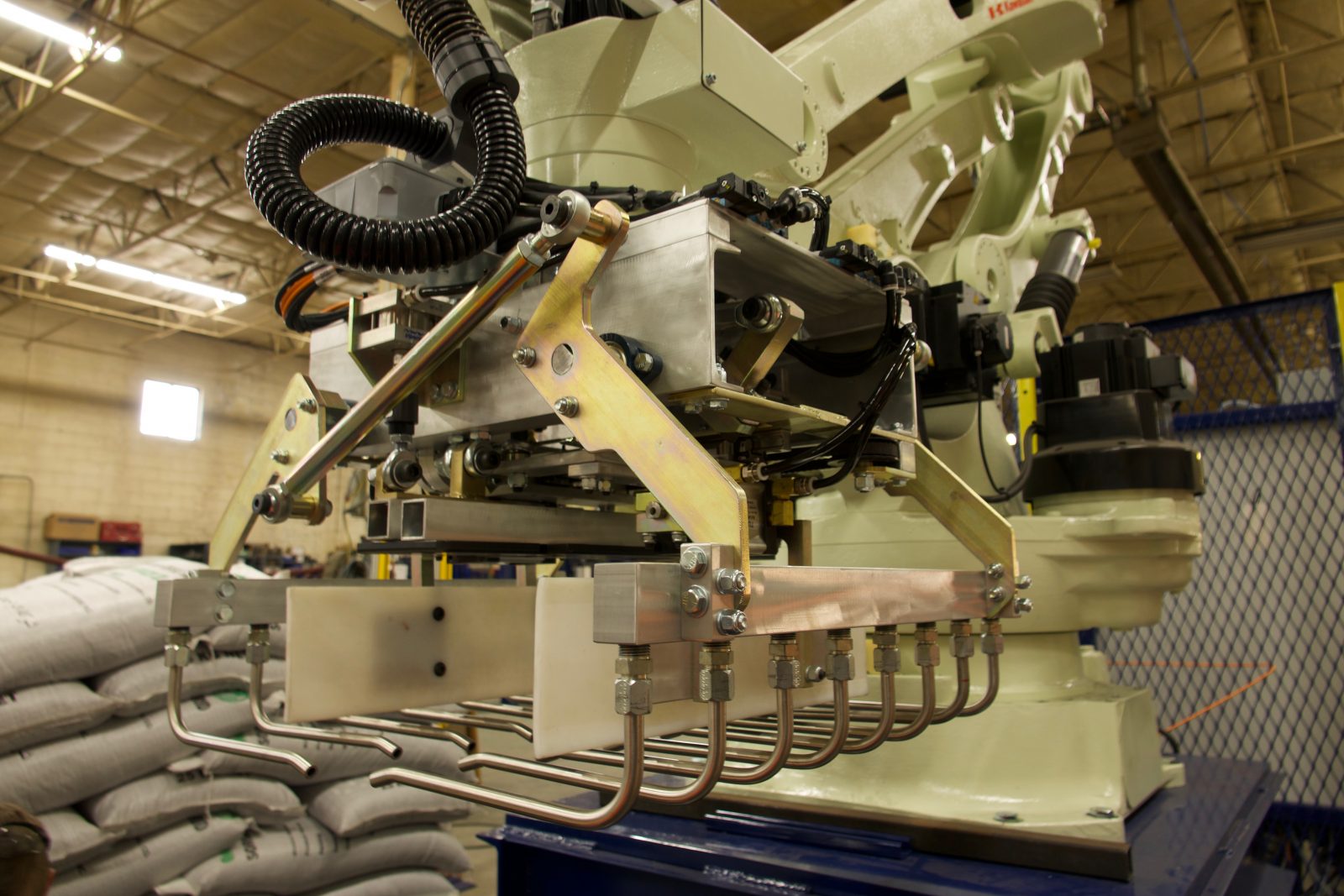

One of the most commonly faced problems for many automation companies is making their equipment easy to clean. There is no room for bacteria and cross-contamination in the food packaging industry, and we understand this completely.

The restrictions and expectations for food companies set by the FDA have become even stricter in recent years, leading to more recalls, and a lower threshold for recall.

One large cause of recall comes from contaminating products being packaged with whatever was being produced on the line before. For instance, if you are making a sugar topping for donuts, you need to be absolutely sure all of the gravy mix has been cleaned out of the machine from last week.

Our machines are as clean and easily cleanable as it gets. When it comes to cleaning your machine, it is all about uptime. It shouldn’t take two days to clean a machine and have it ready to handle a different product.

Human Contamination

Human error causes a large portion of contamination in the food industry.

One terrifying example of this human contamination comes from a meat producer and packager in Tampa, Florida. The producer was forced to recall nearly 712 pounds of frozen beef and pork products due to possible contamination with human blood. A worker had accidentally cut themselves on the line and may have bled into the product.

Chemical Contamination

Chemical contamination occurs when chemicals are present in foods where they should not be. This is often very prevalent when packaging foods.

The long process of packaging foods presents many opportunities for chemicals to enter the product. Oftentimes, food comes into direct contact with packaging materials, leading to the introduction of unwanted chemicals into the product.

Consequences

The consequences of food contamination and recalls are massive. In 2018, a producer of powdered baby milk was forced to recall over 12 million of its products due to salmonella. This costly mistake harmed at least 35 babies.

The company was hurt immensely by this contamination. The financial damage was estimated to be hundreds of millions of dollars in recall costs and settlement costs. This does not even take into consideration the losses the company will face in the future due to customers not purchasing their products.

NOVA Automation

At NOVA, we are here to help ensure your food processing and packaging business stays at the pinnacle of cleanliness. We must move from dealing with contamination when it arises to prevent it entirely. Automating your packaging system is a great way to do this.

Contact us today to find out what we can do for you.